Guide

Guide  A fuel oil furnace or a heat pump – which is more cost-effective?

A fuel oil furnace or a heat pump – which is more cost-effective?

Back

BackChoosing the right heating system is a decision with long-term consequences for both your wallet and the world around you. Nowadays, with environmental awareness growing as fast as energy prices, homeowners are faced with a difficult dilemma: a functional heat pump or an oil-fired boiler? Both solutions have their advantages and disadvantages. It is worth considering them, analysing not only the initial and operating costs, but also the environmental factor.

A heat pump draws energy from natural sources such as the ground, water or air (unlike an oil-fired furnace) and is one of the most technologically advanced tools in the field of heating. Each type of pump has its own specific installation requirements and characteristics to suit different conditions and expectations.

The operating costs of a heat pump combined with photovoltaics – compared to traditional installations – are more than promising. What is more, by using renewable energy, these units significantly reduce greenhouse gas emissions, making them a more environmentally friendly solution. In addition, compared to induction furnaces, the devices described are more practical. Among the disadvantages, we must mention the relatively high investment cost. However, this can be offset by long-term savings resulting from everyday use and subsidy programmes for heat pumps.

Fuel oil boilers, which have been the standard heating unit in many homes for decades, have undergone a significant evolution in recent years. Modern models should be considered much more efficient and practical than their older counterparts.

The biggest advantages of oil-fired boilers are their quick adaptation to existing systems, speed of operation and ease of installation. This is extremely important in buildings without access to natural gas or in places where it may be difficult to install a heat pump. However, when considering oil heating, cost becomes a key factor. Dependence on oil prices on global markets significantly affects current expenses, making this device less financially predictable. In addition, the need for regular maintenance, fuel storage (which requires additional space and appropriate safety measures) and a greater impact on the climate are among the disadvantages of this heating system.

The overriding factor in choosing between a heat pump and an oil-fired boiler is the initial outlay (read more about heat pump costs). The former requires a larger investment at the outset, but is usually much cheaper to run. On the other hand, oil heating initially generates lower costs, which is certainly important information for those on a limited budget. It is also worth remembering that with this type of boiler, you will not be able to take advantage of any available subsidies.

In addition, fuel prices and the need for regular servicing may, over time, tip the balance against this technology. From an environmental point of view, heat pumps have a much better impact on the environment – they emit less CO2 and support sustainable development. Modern oil-fired boilers are easier to keep clean than in the past, but they still have a higher carbon footprint.

Oil-fired boiler or heat pump – this question should be answered based on several important factors: location, space availability, economic and environmental preferences, and individual needs. Pumps are ideal for longer-term use, especially in new or modernised buildings. Oil-fired boilers can be an alternative for users who need a quick and relatively inexpensive installation, but are also aware of the long-term costs and environmental impact. There are many options. Heat pump or pellets? Or maybe – a pump or gas heating? It is important to consider the different options in order to make the best possible decision.

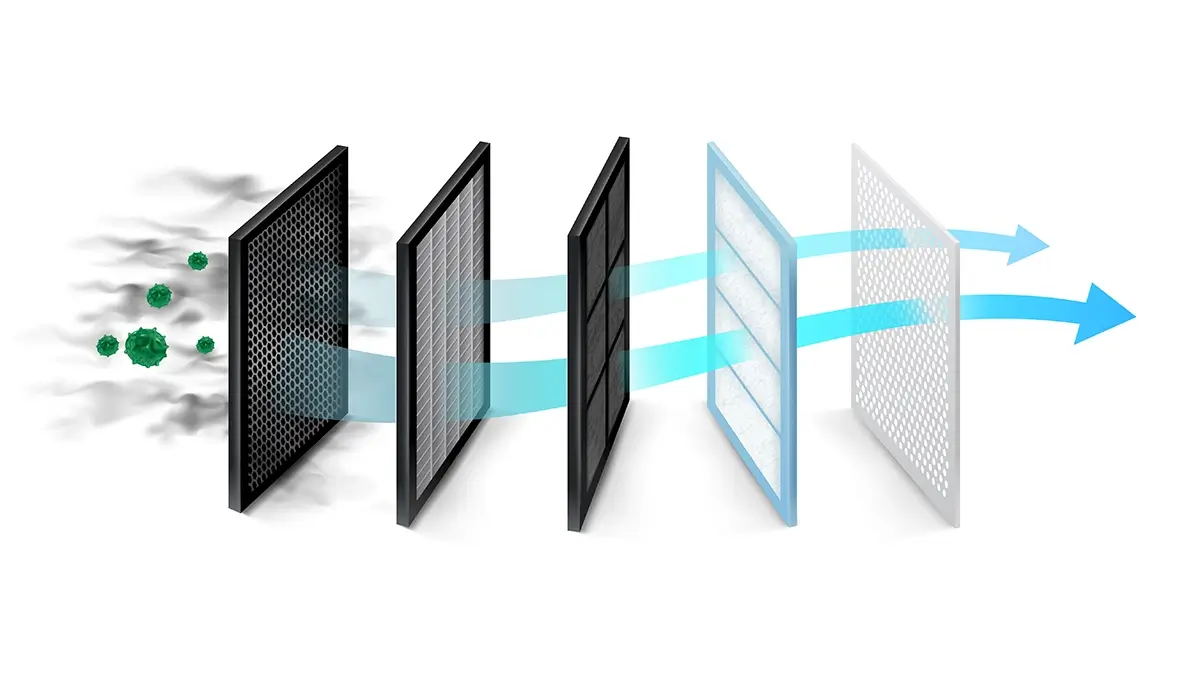

The connection diagram for a heat pump and a fuel oil furnace shows in detail how both systems can be integrated into a single design to ensure reliable heating. Integrating these two mechanisms requires careful planning and expert knowledge. The device takes into account both the connection of the source and the heat distribution system with switching valves, allowing the two units to be linked depending on current needs and external conditions. In addition, we should remember to include controls that allow automatic switching between one machine and another, which will optimise costs and comfort of use. The implementation of the connection diagram for a heat pump and a fuel oil furnace also requires the installation of appropriate safety devices, including filtration systems and separate circuits for energy from different sources, to ensure long-term and trouble-free operation.

It is worth noting that systems using a heat pump and a fuel oil furnace are very rare. Investors are much more likely to decide to combine a pump with an electric heater or a gas boiler.

In an era when sustainability and energy efficiency are becoming important selection criteria, heat pumps seem to be the solution for the future. Investors today pay great attention to good thermal insulation of houses and are looking for solutions that will maximise savings.

On the other hand, oil-fired boilers, although they may seem less attractive, for example from a climate impact perspective, are still attracting interest. In places with limited access to photovoltaics or where existing heating systems require a quick and relatively inexpensive solution, oil-fired boilers are still frequently installed. However, it is worth remembering that current usage fees and potential changes in European Union regulations will affect long-term profitability and will be decisive arguments in favour of heat pumps.